5 Axis Machine Shops: Owens Industries , Inc offers 5 Axis CNC Machining Services and true 5 Axis Fine Wire EDM Machining with micron tolerances (Positional accuracies of 0.5 µm and angular accuracies of .002°). Please visit: http://www.owensind.com/5axis.htm or email Mark Plesnik: info@owensind.com

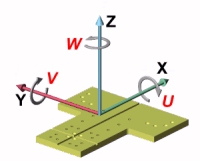

5 Axis Precision Machining: 5 Axis Precision Machining allows machining of all 5 sides in one Set up. While this can certainly be a cost saving factor, 5 Axis machining is used more often for complex contour work, which may need simultaneous movement of all 5 Axes. Current generation 5 Axis machines offer excellent tolerances - as close as 3 microns.

5

Axis

Wire EDM:

In addition to the normal Wire EDM process. A true 5 Axis Wire EDM incorporates

a rotary indexing system under the direct servo control of the Wire EDM machine.

5 Axis Wire EDM actually is on different axes as compared to the 5 Axis CNC

Machining processes. Often, people would consider the tilting of the wire

head as being 5 Axis work. In actuality, true 5 Axis EDM would have a rotary

indexer that could actually rotate the part - even simultaneously during the

Wire EDM process. More commonly, the rotary indexer is actually used to index

on preset increments, for example to create axial slots. A 5 Axis Wire EDM

with fine wire capability would be able to use a .001" diameter wire

and can even offer sub micron tolerances.

Advantages of 5 axis Wire EDM technology: 5 axis Wire EDM can be extremely useful when close tolerances are involved. The use of fine wires with very small diameters in the range of .001-.004" can guarantee a very high precision work on wire EDM machines. Because EDM is a no-contact and no-force process, it is well suited for making frail or fragile parts that cannot take the stress of standard machining, it can cut parts 16 inches tall with a straightness of ±0.0005 inch per side! Parts requiring small inside radii are now easily achieved using this technology. The use of a .001" wire would be that the corner radii can be as sharp as .0015 (there is usually an overburn of .001" during the EDM process). But the most important advantage came with the increased sophistication of EDM controls in rams and the new EDM processes that use simple-shaped electrodes to 3D mill complex shapes with extremes accuracy! Now users demand and need maximum productivity and throughput, increased accuracy, higher angles of taper, thicker work pieces, automatic wire threading, and long periods of unattended operation, make the Wire EDM machining a breakthrough precision technology. 5 axis Wire EDM is used to manufacture complex parts for the aerospace, Medical, and telecommunication Industries

Wire

EDM History:

Introduced

in the late ‘60’s, wire-cut EDM was a unique, breakthrough technology.

Although it has earned respect for its ability to machine difficult workpieces

with unsurpassed accuracy, the machining process didn't gain the full attention

it deserves until recently. Its use spread quickly as its accuracy and effectiveness

became apparent. Since then, wire-cut EDM has experienced explosive growth;

in application, sophistication of equipment, and in the demands made on the

basic tool of the process, the wire.

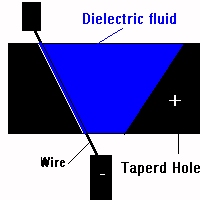

Wire EDM, the technology: The workpiece and the wire represent positive and negative terminals in a DC electrical circuit, and are always separated by a controlled gap, constantly maintained by the machine. This gap must always be filled with a dielectric fluid, in this case deionized water, which acts as an insulator and cooling agent. Of equal importance, it flushes away the eroded particles from the work zone. Sparks are formed through a sequence of rapid electrical pulses, generated by the machine’s power supply thousands of times per second. Each spark forms an ionization channel under extremely high heat and pressure, in which particles flow between the wire electrode and the workpiece, resulting in vaporization of localized sections The vaporized metallic debris created by this process, from both the workpiece and wire material, is subsequently quenched and flushed away by the flow of dielectric fluid through the gap. As the machine advances the wire through the workpiece, it cuts a slot slightly larger than the wire diameter. Since the wire is also eroded away and used up in this process, the machine constantly feeds new wire into the cut as “fresh” electrode material.

Die-sinking

or Plunge EDM:.

In the case of plunge EDM, the required shape is formed negatively in the

metal with a three-dimensional electrode. By superimposed movements in the

main axes x, y, c, z, the most varied shapes, indentations and cavities are

created, such as can not in part be achieved by any other machining system.

For example, a helicoid cavity or a rectangular hole in one single steel block

or the machining of an extremely thin, hardened steel sheet that may not be

subjected to any mechanical pressure. The machining of small precision gears,

or a square with very sharp inside radii.